When you need to span long distances without intermediate support or carry concentrated loads from upper floors in Bell Gardens, structural steel provides the strength and rigidity that wood and concrete cannot match. Projects like commercial buildings, equipment platforms, and large roof structures in Bell Gardens rely on steel beams and columns positioned accurately and fastened securely to transfer loads safely. Gano culwell Enterprises installs steel members according to engineered drawings, working with inspectors and project engineers to ensure each connection meets design specifications.

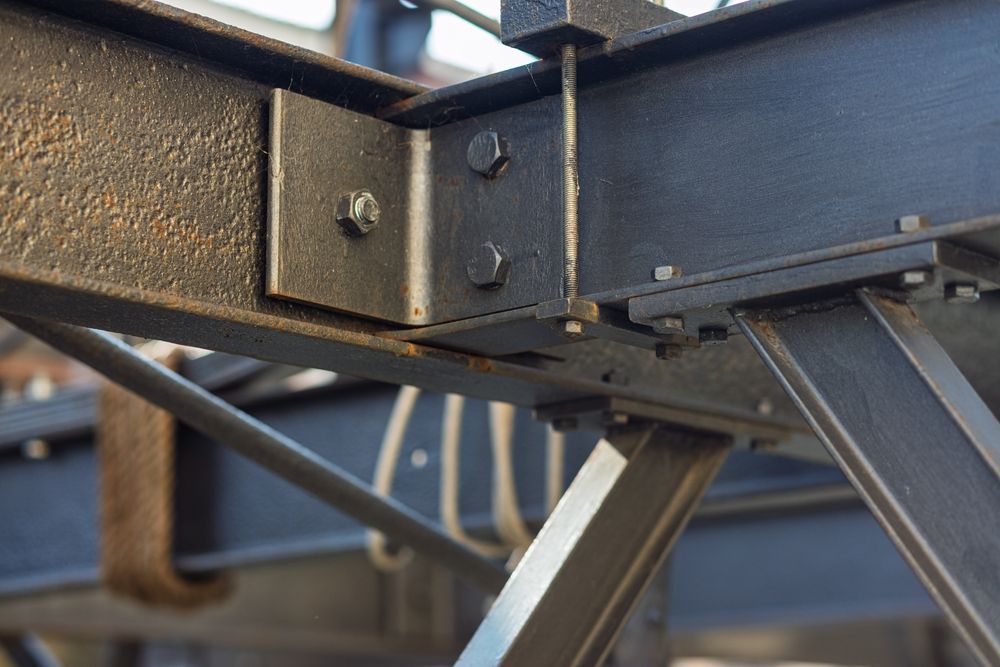

Steel installation begins with reviewing shop drawings that show member sizes, hole locations, and connection details. The crew uses cranes or lifts to position beams and columns, then bolts or welds them to base plates, other steel members, or concrete embedments. Every connection requires torque specifications or weld inspections to verify that load paths work as the engineer intended, and safety protocols govern rigging and fall protection throughout the process.

If your project requires steel framing or structural support in Bell Gardens, reach out to discuss engineering coordination and installation schedules.

What Happens During Steel Placement and Connection

The crew begins by verifying that anchor bolts or embed plates are positioned correctly in the foundation, then lifts steel columns into place and temporarily braces them plumb in Bell Gardens. Beams get hoisted and set onto column flanges or bearing plates, and bolts go through pre-drilled holes to secure the connection. The installation crew checks alignment with levels and laser transits to ensure each member lands within tolerances before final tightening or welding.

After installation, you see a steel frame that holds its shape under wind and gravity loads, with connections strong enough to prevent movement or rotation. The structure supports roof decking, floor systems, or equipment loads without deflecting beyond design limits.

Welded connections require certified welders and may involve ultrasonic or visual inspections to confirm penetration and soundness. Bolted connections use high-strength fasteners torqued to specification, sometimes with turn-of-nut methods for critical joints. The work does not include fireproofing or corrosion coatings unless those are included in the scope, and the installation schedule depends on crane availability and weather conditions safe for rigging.

Property owners and contractors often ask about connection methods, inspection requirements, and how steel installation fits into the overall construction sequence before scheduling lifts.

Gano culwell Enterprises coordinates steel delivery, crane scheduling, and inspector visits to keep your project on track without weather delays or rework. Get in touch to review your structural drawings and confirm installation timelines for your Bell Gardens site.